News

IFAT MUNICH 2022

From May 30 to June 3, 2022, everything revolves around the theme of “Recycling” in the city of Munich. In an area of 3,384 square meters, ROTER RECYCLING will present a NEW BALER for ELV, in collaboration with the SEDA team that will always be available to answer your questions!

Roter Recycling at WASTE EXPO 2017, 9-11 May, New Orleans LA

We will be attending the WASTE EXPO 2107 Exhibition in New Orleans LA, 9-11 May 2017, Ernest N. Morial Convention Center, Booth: 3729 We Will look forward to meeting you on the day.

RR6 in Melbourne area

Are you thinking a new and completely customized machine for your scrap yard?Please go trough SALES NETWORK and ask to your country’s dealer for further information.

IFEMA Madrid 15-17 Junio 2016

ROTER RECYCLING y Pac Machinery participara en el Salón de la Recuperación y el Reciclado (SRR) en el Foro de Soluciones Medioambientales Sostenibles que tendrá lugar en el IFEMA (Madrid) los dÃas 15 a 17 de junio. SRR reunirá a las empresas que presenten las últimas innovaciones en maquinaria y servicios para tratamiento,

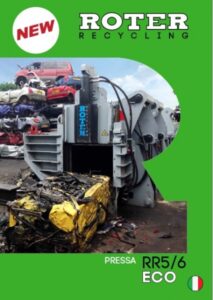

New RR5-6 ECO

RR ECO” serie The best compromise between efficiency and performance. RR5-6 ECO balers has very low operating costs, but same force of RR serie balers. The right choice for those looking for a cheap product but with strength and reliabilitythat distinguishes Roter Recycling balers worldwide.